Electric System Analysis And Trouble Shooting Of Bulldozer

Jul. 21, 2021

Jul. 21, 2021

The 2021 China Machinery Industry Internet Conference (CMIIC) was held in Qingdao, Shandong Province this month. The bulldozer, this huge object, attracted many people's attention in the meeting place.

Intelligent manufacturing, Industrial Internet of Things, the development of high-altitude working platform industry, bulldozer market, mining machinery, the sharing theme of each conference is the most focus of the current industry and enterprises. Bulldozer this huge object, in the meeting place, has attracted the attention of many people, its future development also has broad prospects.

This article is about how to correctly judge the fault of the electrical system of the bulldozer and eliminate it in time so that the work can proceed smoothly. For a service and maintenance staff, first of all should be familiar with the electrical principle of the system, so that the failure of the system analysis and judgment, avoid detours, to achieve twice the result with half the effort.

The electrical system of bulldozer and road roller is 24V DC system, which adopts single wire system and negative pole. In the fault judgment, should first ask the fault situation, observe the fault phenomenon, in the hands-on inspection, should be in line with the first easy then difficult principle.

Routine inspection

When the starting switch rotates to ON, whether the battery relay acts. If so, the main circuit of the system is connected. At this time, the voltmeter ON the instrument panel indicates the voltage of the battery, so as to preliminarily judge the state of the battery.

Fault detection

1. Starting line

when the bulldozer is in the stop state and the starting switch is in the OFF position, the voltmeter will have voltage indication.

This fault indicates that the battery relay is not disconnected, which will cause the battery to discharge. For a long time, the battery will lose power and cause difficulty in starting.

Possible causes of failure:

A. Battery relay failure.

B. There is a break in the terminal post of the battery relay (observed).

C. Start switch malfunction.

D. There is a break in the starting switch terminal (observed).

E. Line failure.

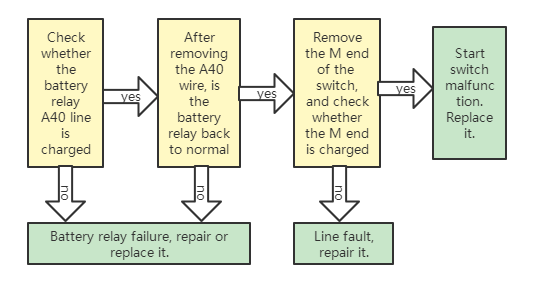

Method: With the help of a multimeter, check whether the battery relay A40 terminal is charged.

2. Stop operation

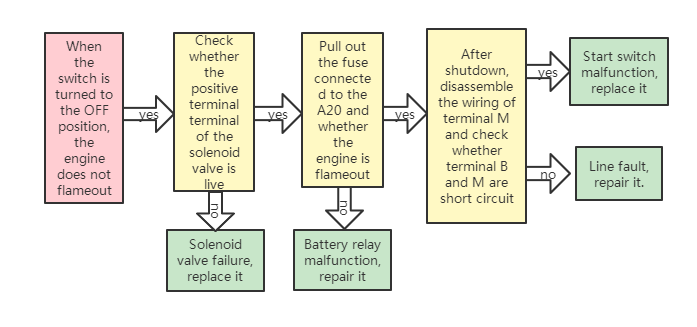

The engine equipped with solenoid valve, when the starting switch turns to the OFF position, the solenoid valve power OFF, to achieve shutdown. If the shutdown cannot be realized when the starting switch is turned to the OFF position, the possible causes of the failure are as follows:

A. Start switch malfunction.

B. Line failure.

C. Solenoid valve failure.

D. Battery relay failure.

Method: Use a multimeter.

3. Voltmeter

When the starting switch is turned to the ON position, the voltmeter indicates the battery voltage (battery rated voltage is 24V); When the engine is working, the voltmeter indicates the generating voltage of the generator (the rated voltage of the generator is 28V); If the voltmeter has no indication or the indication is inaccurate, the possible cause of failure is:

A. The voltmeter is malfunctioning.

B. Line failure.

C. Sensor failure.

Methods: Use a multimeter

Now here are the ways to fix and repair a bulldozer. If you want to wholesale bulldozers of different types, such as T series and SD sereis, welcome to HBXG and find them. Xuanhua Construction Machinery Co., Ltd. (Hereinafter referred to as HBXG) was founded in 1950. HBXG is the pioneer of the track bulldozer manufacture in China. Now it has become a state-owned public company, a leading manufacturer of bulldozer, HBXG locates in Xuanhua, a historic city in the Northwestern of Hebei Province with only 175 kilometers away from Beijing, capital of China.